Plastic Injection Moulded Components Manufacturers, Suppliers, Exporters In Salem

New Modern Plastics serves as the Plastic Injection Moulding Components manufacturers in Salem. Our Plastic Injection Moulded Components manufacturers believe in taking full responsibility for our projects and managing all aspects from design and validation to mould and component manufacturing.

All our machines are equipped with hopper dryers and other auxiliary equipment such as mould temperature controllers, hot runner systems, etc. We have decades of experience in providing moulding and tooling solutions for precision injection moulded parts with strict adherence to manufacturing best practices supported by on data that brings visibility to manufacturing processes.

Description

Plastic injection moulded components are parts that are formed by injecting molten plastic into a mould cavity and then cooling it to solidify. Some features of plastic injection moulded components are: –

- Uniformity and consistency in shape, size, and quality due to the high repeatability of the process.

- Complex geometry and detailed features that can be achieved by applying high pressure and using precise moulds.

- Versatility and customization in material, colour, and design by using different types of plastic polymers and additives.

Advantages

- Plastic injection moulded components have low cost and high efficiency due to the fast production rate, low labour cost, and low waste generation of the process.

- These components have high performance and durability due to the stability and strength of the plastic material and the ability to withstand various environments.

- They have recyclability and environmental friendliness due to the possibility of reusing the scrap plastic and reducing the material consumption.

Specifications

| Product Name | Plastic Injection Moulded Components |

|---|---|

| Brand | New Modern Plastics |

| Tolerance (in mm) | +/- 0.001 – 0.025 mm |

| Components Type | Injection Moulded |

| Application | Industrial |

Demystifying the Machine: A Look at Plastic Injection Moulding Components

Plastic injection moulding is a ubiquitous manufacturing process that shapes our world. expand_more From the water bottle in your hand to the intricate components of your car, countless plastic parts rely on this technique. But have you ever wondered how exactly this process works? The magic lies in the intricate interplay of various components within an injection moluding machine.expand_more Today, we’ll delve into these components and understand their roles in bringing plastic parts to life.

The Mold: The Heart of the Process

The mould is the center piece of injection moulding. It consists of two main parts: the cavity and the core.expand_more The cavity defines the final shape of the plastic part, while the core can form internal features or hollow sections.expand_more Molds are typically made from steel or aluminium for durability and are precision-engineered to ensure part quality.

Inside the mould, you’ll find a network of channels that circulate a coolant, typically water.expand_more This cooling system rapidly solidifies the molten plastic, ensuring the part takes its desired shape.expand_more

Injection Molding Machine Mold

The Injection Unit: From Pellet to Molten Plastic

The injection unit is responsible for transforming solid plastic pellets into a molten state.expand_more Here’s a breakdown of its key components:

- Hopper: This funnel-shaped container holds the raw plastic pellets.

Injection Molding Machine Hopper

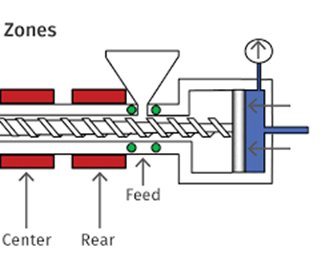

- Barrel: The plastic pellets are fed into the barrel, a heated cylinder. expand_more Here, a rotating screw mixes and melts the plastic while it moves forward.expand_more

Injection Molding Machine Barrel

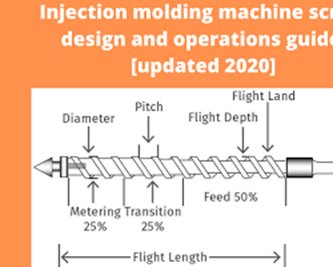

- Screw: This critical component acts like a conveyor belt, pushing the melted plastic towards the mold.exclamation

Injection Molding Machine Screw

- Nozzle: The nozzle connects the barrel to the mold cavity. It acts as a gateway for the molten plastic to enter the mold.expand_more

Injection Moulding Machine Nozzle

Additional Components for a Smooth Operation

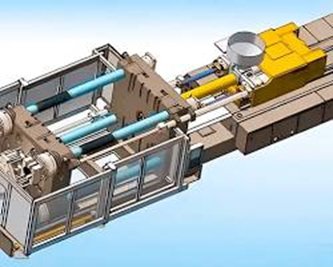

Several other components play supporting roles in the injection moulding process:

- Clamping Unit: This unit applies a strong force to hold the mould halves together during the injection process.expand_more

Injection Molding Machine Clamping Unit

- Ejector Pins: Once the plastic cools and solidifies, ejector pins push the finished part out of the mold cavity.expand_more

Injection Moulding Machine Ejector Pins

- Hydraulic Unit: This unit provides the necessary hydraulic pressure to operate the clamping unit and the injection unit.

- Control System: The control system is the brain of the operation expand more It monitors and regulates factors like temperature, pressure, and cycle times to ensure consistent part quality.expand_more

Understanding these components provides a deeper appreciation for the complexity of plastic injection moulding. By working together seamlessly, these parts turn raw plastic into the countless shapes and objects we use every day.

Related New Modern Plastics Injection Moulding Components Areas:

Chennai, Coimbatore, Sivakasi, Erode, Salem, Tiruppur, Pondicherry, Trichy, Madurai, Namakkal, Karur, Kerala, Kochi, Ernakulam.