Leading Industrial Small Tension Springs Manufacturers in Kerala”

Located in Kerala, New Modern Plastics is a premier manufacturer of industrial small tension springs. With a focus on precision and quality, we cater to various industries including automotive, electronics, and machinery. Our state-of-the-art facility is equipped with advanced machinery, allowing us to produce durable and high-performance tension springs. We offer customized solutions to meet specific client requirements, ensuring each spring meets exacting standards. Our commitment to excellence ensures timely delivery and competitive pricing, making us the preferred choice for industrial small tension springs in Kerala. Choose us for reliable, high-quality spring manufacturing solutions.

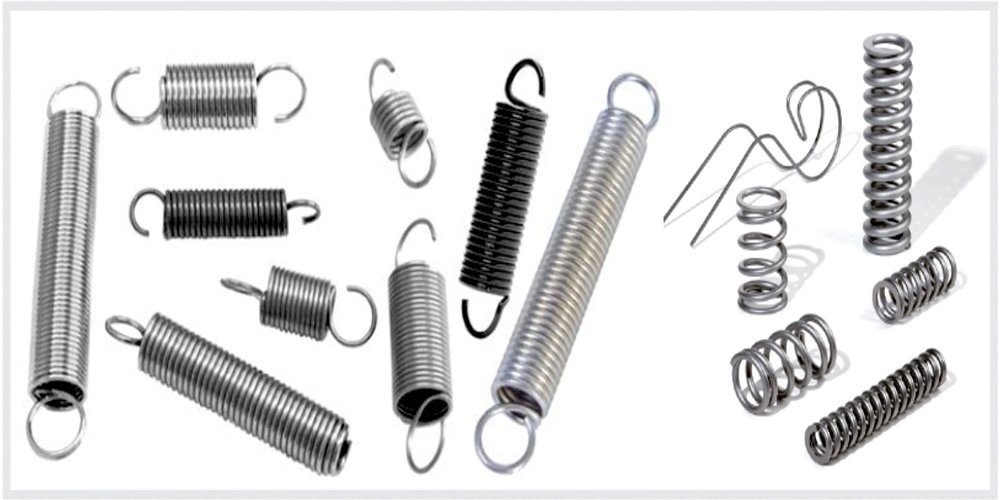

Extension springs are designed to absorb and store energy as well as create a resistance to a pulling force. It is initial tension that determines how tightly together an extension spring is coiled. This initial tension can be manipulated to achieve the load requirements of your particular application.

All New Modern Plastic’s springs are wound with an initial tension force which offers a small deflection load for secure installation “holding”. The initial tension is equal to the minimum force required to separate adjacent coils. Each spring is of the constant diameter type with a variety of hook/loop styles. Spring Anchors are also available.

MATERIALS

The highest grades of spring wire are used in manufacturing Century Spring products. Certifications of conformance for geometric tolerances for our stock springs are available upon request. We only offer material certifications for custom springs.

“Spring steel” is a term that includes music wire, hard-drawn wire and oil-tempered wire. Alloy steels for stock extension springs are offered only in 300 series stainless. New modern Plastics is the No.1 Springs Manufacture And suppliers in Cooimbatore

How Tension Springs are Made by New modern Plastics Kerala?

Tension springs are mostly made of metal, and their type depends on the amount of stress it is exposed to and other environmental conditions. The materials that are mostly used are:

- Copper Alloys

- Stainless Steel

- Spring Steel

- Titanium Alloys

- Low Alloy Steel

- Cold Rolled Steel

The manufacturing process of tension springs is done with highly-advanced hot and cold coiling procedures. The wire is bent, heat-treated, and finally finished or coated to protect the spring from corrosion or humidity. Tension coiling machines manufacture springs of dimensions between 0.004 to 1 inch (0.1 to 26mm).

Characteristics of Tension Springs

- Tension springs stretch and create a load.

- Tension springs have a little gap between the adjacent coils, and the load is applied along its axis.

- Tension springs are durable and designed with great precision.

- These springs have dimensional stability and high tensile strength.

Working of Tension Springs Manufactured by New Modern Plastics Kerala

A tension spring is a helical spring with tightly wound coils. These springs operate under applied tension. When the spring is at rest, no load is attached to its ends; the coils touch each other and are in a compressed shape. When an external force is applied, the spring stretches to a specific length. This means the components attached to spring ends pull them apart, causing tension in the spring. This makes the spring come back to its original position.

Lifespan of a Tension Spring

The lifespan of a tension spring depends on the following factors:

- Frequency of use

- Spring application

- Material of the spring

- The environment of the spring

- Amount of the stress that is applie

The lifespan of tension springs is mainly determined by environmental factors. Exposure to sunlight, chemicals, corrosive agents, and water affects the integrity of the metal. Continuous load exposure also causes metal fatigue in the springs, which causes microcracks in its structure.

Types of Tension SpringsManufactured by New Modern Plastics Kerala

Many types of tension springs depend on the type of hooks or loops attached to their ends. These loops differ from one another and depend on the application type. Some of these types are as follows:

- Machine Hooks

Machine hooks are the most commonly used ones. It is the strongest of all the hooks because the bend radius is not pronounced. Bending ¾ of the coil can make machine hooks.

- Cross-over Center Hooks

Cross-over center hooks are the second most commonly used hooks. The bent radius for these types of hooks is pronounced. These hooks are made by lifting the last coil and twisting it in the middle.

- Side Hooks

Side hooks are ideal to use when body interference is not required during the mechanism. As the name suggests, the hook is on one side of the spring. These hooks are made by bending the last coil and are more economical than other types.

- Extended Hooks

These hooks are the same as used in side hooks. These are useful when there needs to be a long length inside the hooks but a shorter body. The extended hooks are the most expensive type of hooks.

- No Hooks

Tension springs with no hooks are the most economical ones. These are good to use as they are stress-free, and they have no trace of fatigue at the ends due to the non-presence of the hooks. Springs with no hooks have an increased pulling force and a higher lifespan for the spring.

Related Industrial Small Tension Springs Areas :

Chennai, Coimbatore, Sivakasi, Erode, Salem, Tiruppur, Pondicherry, Trichy, Madurai, Namakkal, Karur, Kerala, Kochi, Ernakulam, Bangalore, Calicut, Manjeri, Kannur, Kollam, Kottayam, Mannarkkad, Malappuram, Payyanur, Thrissur, Dindigul, Trivandrum, Mysore, Hosur